6-t Excavator Redesign

Exciting news: The SUNCAR 6 t electric excavator will soon be revised! In addition to technical innovations and improvements, the new edition will also have a new design.

See the original article in E-Mobility Magazine: Website E-Motec

The electrification of vehicles has definitely arrived in the off-road sector as well. But unlike the on-road sector, there is a greater variety of equipment available in the off-road sector – from electric vibratory plates to a 55-ton large rotary drills, it’s all there. However, the inconsistent application and relatively small customer base per vehicle type makes it more difficult to achieve the economies of scale that their on-road counterparts do, and that’s a key factor when it comes to heavy-duty electrification. Barriers such as sheer size of the vehicle and power requirements, charging infrastructure, the broad range and intensity of duty cycles, and the length of downtime for recharging have made electrification of off-highway vehicles slow to take off. However, better performance, controllability and flexibility, and lower maintenance costs will play an important role, not to mention the environmental benefits.

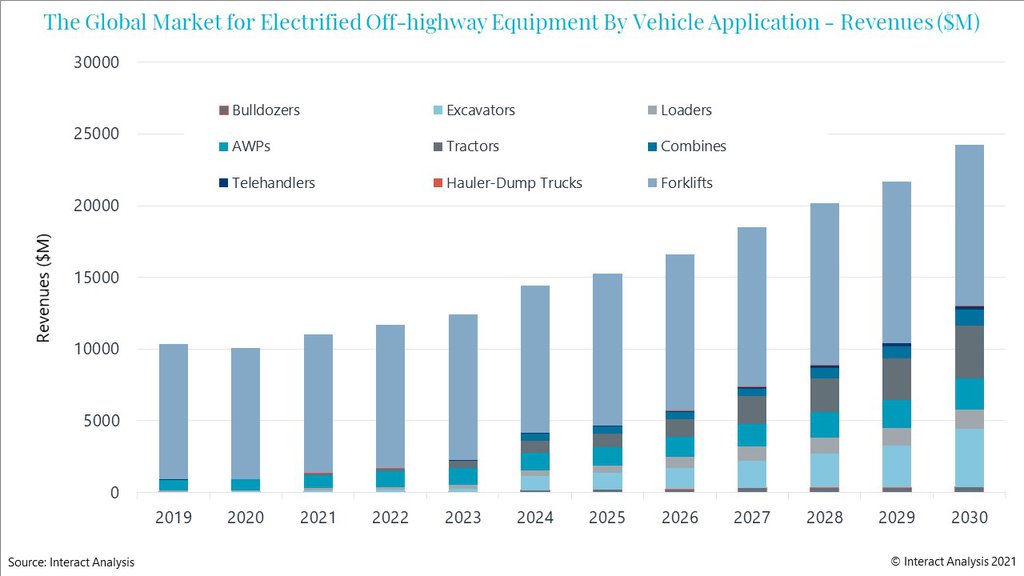

Analysts from Interact Analysis have found that the global market for electrified components for off-highway vehicles will be about $10 billion by 2020. This figure is expected to increase up to $25 billion by 2030, with a CAGR of 8%, with total sales reaching $186 billion between 2019 and 2030. The forklift market, by far the most mature in terms of electrification, currently accounts for the majority of electrified component sales, but this will change as new electrified technologies suitable for other applications such as excavators and tractors enter the market.

Here we take a closer look at the market for electrified components, especially DC fast charging interfaces and high-voltage distribution units (in the following also referred to as HVDU).

A high voltage distribution unit is utilized to distribute currents and voltages within the high voltage system of the electrification project. For the e-mobility sector, the unit provides energy from one or more energy sources such as batteries or charging devices and distributes it to all consumers as for example the main components battery, charger, inverter, motor, and optionally also the fastcharging system. Depending on the type of current load, the individual inputs and outputs are protected against overcurrent with fuses.

The distribution of the currents can be designed as active or passive. In passive distribution, the outputs are connected in parallel, while in active distribution contactors control the distribution to the outputs.

Contactors are electromechanical switches that are opened or closed by using an excitation voltage and a built-in coil. Contactors are used to switch DC voltages with high currents for safety reasons e.g., to protect fast charging inlets.

Additional functionalities that a high voltage distribution unit could offer:

Regarding safety in the high voltage system, the following challenges need to be mastered:

Typical areas of application for the high voltage distribution units discussed here are electrified machines and vehicles with increased demands on robustness and safety, such as heavy-duty, commercial and municipal vehicles.

As the high voltage distribution unit discussed here is a product with an application range in a high voltage range up to 800 VDC or more, special expertise in handling and operating the product is required.

The vehicle should be able to be free of voltage most quickly and safely possible, and this as far as possible without mechanical wear. For this purpose, an HV switch could be integrated into the high voltage distribution unit, which separates the consumer side from the battery side. The two sides will then be clearly separated in terms of contact protection within the product. Due to this measure, the consumer side can be safely disconnected by actuating the HV switch without having to remove the battery plugs. If service work is to be carried out on the battery or the battery wiring, the battery side must also be disconnected. The two parts of the HV system (consumer and battery side) are clearly separated and labelled.

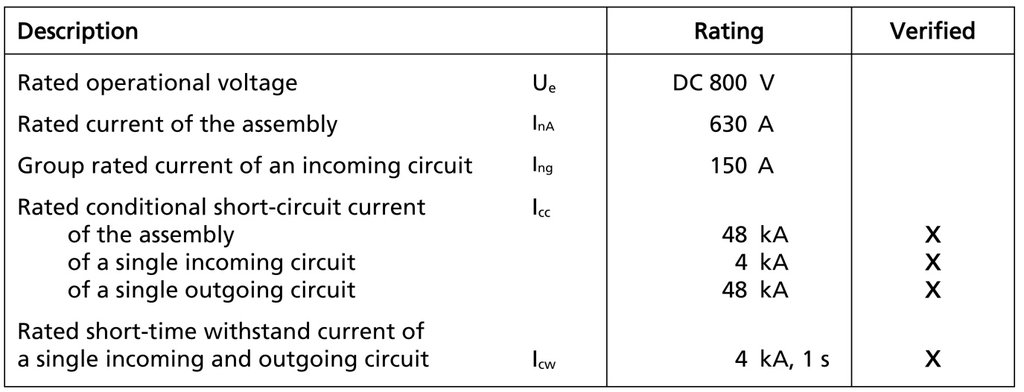

The high-voltage distributions lay an important foundation for safety in the event of overcurrent – this has the important function of significantly protecting the vehicle and the driver. It is therefore very important to verify short-circuit currents, ratings and characteristics assigned by the manufacturer, and to test the equipment extensively to absolutely avoid overloading or, in the worst case, a fire.

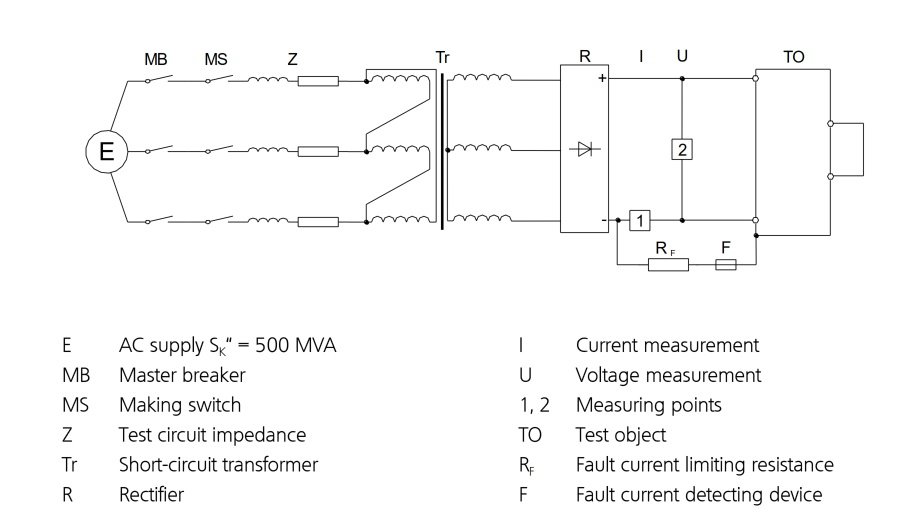

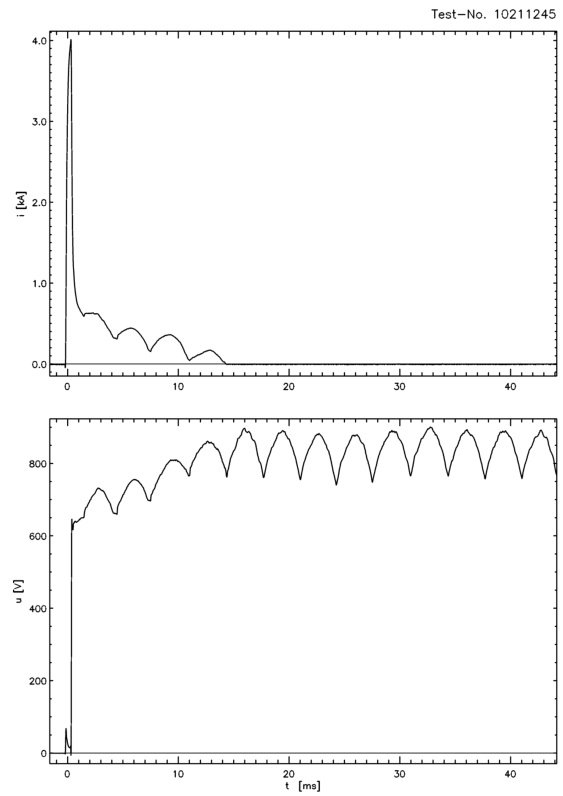

The verification of short-circuit withstand strength is tested with the following measuring circuit. The feeder conductors and short-circuit bridges required for evaluating the switchgear and control gear assembly must have sufficient short-circuit strength and must be arranged in such a way that they do not represent an additional load on the switchgear and control gear assembly.

The following tests show that the high voltage distribution unit with corresponding fuses could withstand a short circuit of multiple batteries at all inputs.

Each electrification project now and in the future will need a high voltage distribution. Thereby the spectrum ranges from small complexity up to huge and very complex integrations. Needed are small junction boxes with only a few fuses as well as highly intelligent high voltage distribution units with active and passive elements for various purposes. And because the markets will continue to grow rapidly, the vehicles must have a good service life and high robustness, which can lead to a good reputation, among other things.

The rapid growth of the markets will also mean that certain components will be available at lower prices in the future: in this context, for example, more favorable power distribution via power board technology would be relevant for high volumes.

In the future, there will also certainly be higher intelligence fuses and switching elements (contactors) that report their status back to the vehicle control system. This will make it possible to map many additional functions in the HVDU to further ensure safety and further reduce costs to run electric vehicles. Another challenge is the combination with DC charging options directly integrated into the systems.

To sum up, our focus and drive is always on technological progress – and thus the focus is on increasing efficiency in each specific application, regardless of having its own product portfolio. “We will remain in the field of intelligent alternative propulsion technologies, always improving and simplifying all products and ensuring maximum safety – and thus continuing to give impetus to the green transition”. - Stefan Schneider, Managing Director of SUNCAR

Wir begleiten Sie, von der Machbarkeitsstudie, über die Konzeption und Konstruktion bis hin zum Bau des Prototyps oder einer Kleinserie und darüber hinaus.